3D Printing Enables Fabrication Agility

In recent years, 3D printing has exploded in popularity with both businesses and hobbyists alike, due to rapid improvements in the technology and the ever-increasing affordability of owning and operating a system. While 3D printing cannot yet replace traditional manufacturing for most production parts, it has become an extremely effective tool for conceptualization, prototyping, custom tooling, and display modeling for presentations and trade shows.

3D printing is one process under the broader umbrella of the field of additive manufacturing.

What is additive manufacturing?

Additive manufacturing refers to any process where material is added to create a part, as opposed to subtractive manufacturing processes like traditional CNC machining. 3D printing is a form of additive manufacturing in that it deposits material layer by layer per design, creating three dimensional objects.

Early 3D Printing

3D printing was first conceived in the early 1980s as stereolithography (SLA), which uses a UV light source to cure a liquid polymer resin, building layer after layer until the model is complete. SLA has the advantage of being highly accurate and offering a nice surface finish. However, it has several major drawbacks that have discouraged widespread adoption. The liquid resin is expensive, messy, and potentially toxic depending on the specific material. The machines themselves have also been expensive, though this cost has come down in recent years. And finally, SLA-printed parts require fairly extensive post-processing: parts have to be washed with a solvent, and then post-cured in an oven.

Evolving Additive Technology

The next additive technology to come along was laser and electron beam sintering. This process uses a laser or e-beam to melt powder into thin layers, eventually building a precise 3D model. The major benefit of laser sintering is that it offers a wide range of materials, including plastics, glass, ceramic, and metal. The use of these materials, especially metals like aluminum, allow laser sintering to actually produce production parts. The biggest downside to this technology is still the up-front cost of the machine; most of the available machines still retail for over $100,000, but lower cost models are beginning to hit the market.

The most recent, and by far the most popular, additive technology is fused deposition modeling (FDM, sometimes abbreviated FFF for ‘fused filament fabrication’). This is what immediately comes to mind when most people picture a 3D printer: plastic filament is extruded through a heated nozzle, being built up in thin layers until the model is complete. The patent for this technology expired in 2009, and since then, prices have plummeted. The printers themselves can be made very simply, which has allowed quality units to retail for under $500. On top of that, the printed materials are inexpensive; 1 kilogram of PLA (polyactide) can be purchased for around $80. FDM is not as accurate as SLA, nor can it produce production parts like laser sintering, but it still has many uses, and the cost of ownership makes it an attractive option for many people.

3D Printing Helps Solve Problems Quickly & Cost Effectively

One of the most common uses for 3D printers is prototyping. Prototyping can be an expensive step when creating a new product. Small order volumes often come with an increased price tag, because the time spent programming, setting up and validating parts is essentially the same whether a machinist is running off 3 parts or 300. 3D printers on the other hand don’t require special setup for different parts, and slicing software can take you directly from a CAD model to fabrication in less than a minute. While the accuracy isn’t the same as a CNC machined part, in most cases, it is enough to validate the design and inform engineers on improvements and next steps.

Another common use case is custom tooling for use in traditional manufacturing processes. This can be custom workholding for a CNC machine, end effectors for a robotic arm, chucks for a lathe, replacing expensive consumables with a cheaper option, and many others.

3D printing is also entering an exciting period where it is being used to solve problems that affect millions of people. In Africa, a company is producing low-cost sustainable housing with a massive gantry-style 3D printer that extrudes fast-hardening concrete. Several cruelty-free meat companies are beginning to use special 3D printers to produce products that closely mimic real meat using plant-based materials. And aggressive research is being performed in the field of 3D bioprinting, which has the potential to revolutionize medicine by producing custom human tissue.

How 3D Printing Helps our Prototyping and Custom Work

Here at Andover Corporation, we have put our own 3D printer to work helping us improve our optical filter manufacturing processes and assist with engineering and 3D prototypes for our custom work. This has led to both a reduction in cost and lead time for our customers as we continue to push the limits of what 3D printing can do for us.

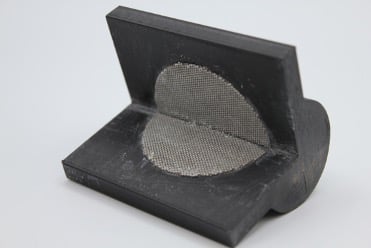

We recently completed a job that required us to mill a hole at 45° angle through a flat piece of glass. Rather than spend significant machine shop time and materials, we designed and 3D printed consumable tooling for pennies on the dollar when compared to traditionally fabricated tooling.

(45° mounting jig)

When we were having issues with the brass chucks on our auto-centering machines scratching coated filters, we started 3D printing the chucks instead, which helped eliminate the issue. Burs would develop over time in the brass, which would then scratch our coatings. But the move to soft plastic chucks worked wonders, and saved us money versus ordering new ones.

(3D printed chucks)

A 3D printed handheld tool is allowing our polishing technicians to quickly break the edges of parts before they are run through our double-sided polishers, improving quality and reducing the potential for damage to the machine and product.

(3D printed chamfering tool)

We’ve also printed many models for visualization, both for our trade show booth, and to help people understand the scale of a job or to help flesh out an idea. 3D printing has become an invaluable part of our manufacturing environment, and will only continue to grow in popularity and importance as the technology improves and cost of ownership increases.

Request a Quote: https://www.andovercorp.com/contact/get-a-quote/