ISO 9001 - AS 9100 - ITAR Toll Free (US): +1 (888) 893-9992 International: +01 (603) 893-6888

DISPELLING THE MYTHS ABOUT LAMINATED OPTICAL FILTERS

Published by Joshua Jones on

Jun 8, 2021 4:33:36 PM

|

Myth: Traditional laminated glass filters do not last .

This is also a misleading statement. Andover Corporation has optical filters in space that have been operating effectively for decades. Andover Corporation uses epoxy purification techniques, detailed curing methods, construction and scribing procedures to extend the life of traditional filters. This is important for equipment manufacturers to know.

The question is; do I purchase a $25 to $90 optical bandpass filter that will last 10 years, or a $300 to $500 filter that will last 30 to 40 years? A typical manufactured piece of equipment (for OEM) has a life cycle of 5-10 years. In 5-10 years a company will release another product version that is more effective than the first. It is a rare case that an optical filter needs to survive 30 years. However, there are some cases where this is true, Andover’s traditional filters can last decades in space, and as long as 10 years here on earth.

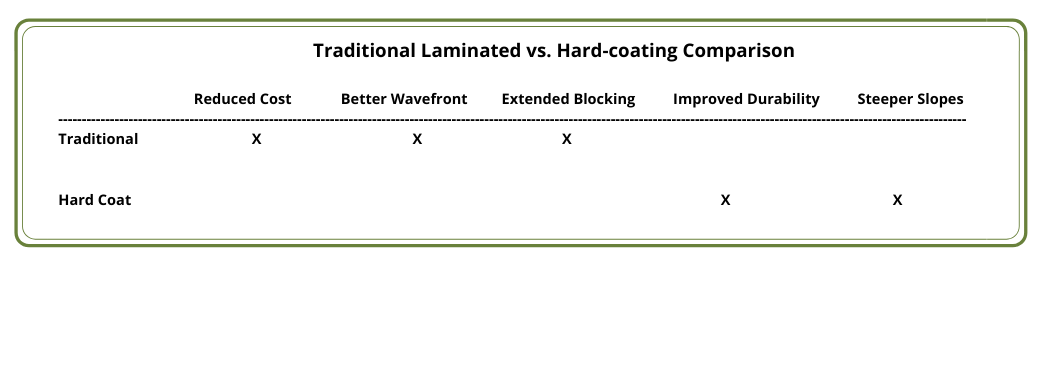

Hard coating first surface thin films are a significant advancement in coating technology and has many benefits. However, it also has disadvantages other than just price. A large disadvantage of first surface hard coatings, created by Magnetron Sputtering or Ion Beam Sputtering, is the build-up of stress. This tremendous stress will distort the optical surface of a filter, creating a distorted transmitted wavefront with reduced image quality. If the hard coating film is of considerable length (and they usually are) then the optic can be visibly bent like a potato chip if the substrate is not thick enough.

A second disadvantage is limited blocking range, because it requires so many layers and long coating runs (sometimes a full week) to block the NIR. If your application requires it, keep in mind, that traditional laminated filters can block the entire out-of-band spectrum regardless of whether it is in the ultraviolet, infrared or visible spectrum.

In conclusion, when choosing the appropriate specifications and requirements for an optical bandpass filter, be sure to consider the true facts about what is really needed. Andover Corporation’s design and quotation team can help refine specifications to get you the correct bandpass filter for your needs. In this way, Andover can help limit any unnecessary costs that may be driving your project. Let us prove it to you.

Tags:

Optical Filters,

Best Optical Filter,

Compare Optical Filters,

Optical Filter Manufacturers,

Optical Filter Designers,

Optical Coatings,

Laminated Filters